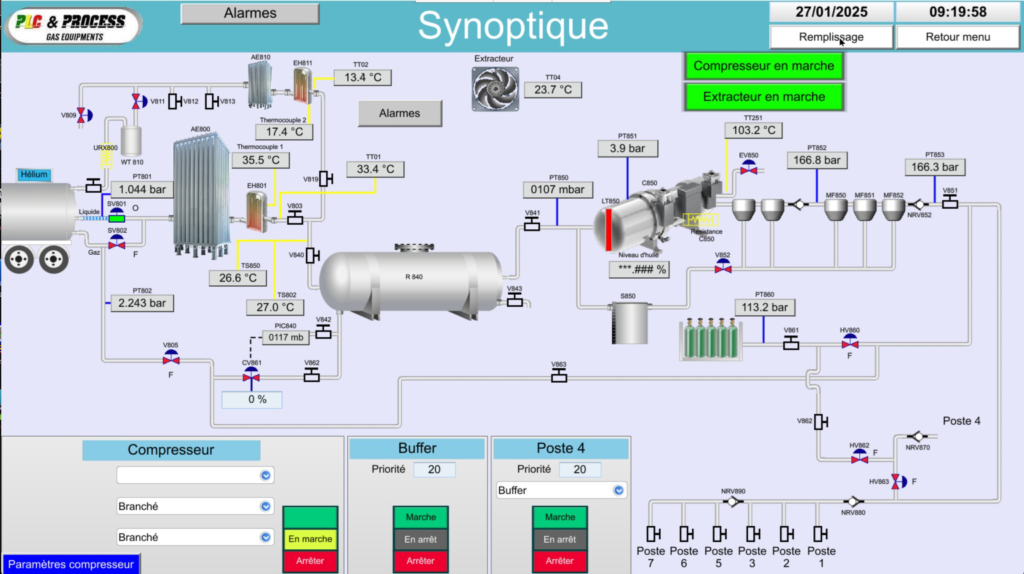

Gas pump control panel:

Oxygen

Argon

Nitrogen

Carbon Dioxyde

Nitrous oxide

Helium

*Hydrogen

Pump control panel can pilot motor from 5.5kW to 140kW on standard applications.

*Hydrogen need ATEX special control panel and installation

Why would you choose our pump control panel ?

Medical and food application

Full traceability is available in the system, including an alarm history feature to track the different alarm during cycle.

Plug and Play

If you already have a frequency invertor and you want to keep your money, no worries, we can use your existing material and connect it to our system.

Flow management by frequency invertor

Our pump control panel uses a frequency inverter to fine-tune filling flow for more precise cycles.

CO2 Heater management

The process of CO2 filling involves a unique procedure where the CO2 needs to be heated to 60°C to be gasified. To achieve this, a water bath is utilized to heat the CO2, which is regulated by three resistances in the water and a propeller to maintain a consistent temperature within the water bath.

He/H2

Special applications are required for handling both hydrogen (H2) and helium (He). By utilizing a compressor, liquid gas can be received in a trailer and then compressed to fill cylinders. It’s important to remember that hydrogen also needs to comply with the ATEX requirement. Plc Process has the capability to develop an ATEX installation.

A booster can be used for He using full cylinder, refer to Stopramp for this feature.

RFID Access

Optional :

No longer necessary to input your password for authentication or system access! Our system now offers the option to integrate an additional RFID reader for both low and high frequencies.

Cold filling

With a regulated heater driven by a by-pass valve. We manage the output temperature with cryogenic liquid to reduce cylinder’s temperature during filling process

PLC Connectivity

This system can be connected to the E-Connect and be managed to start the cooldown when the product is asked by one of our system.

Trends

Follow all the data from the pump panel screen. Pressure, temperature, leak detection, tank level and pressure. Be sure to have everything connected !

Technical description

| Power supply | 400 Vac+GND |

| Connection | Ethernet T568B |

| HMI | 7″ touch screen |

| Frequency invertor | 5.5kW to 140kW |

| Output for valves | 24VDC 0.5A |

| Pressure sensors | 4/20mA |

| Temperature sensors | PT100 |

| Level and tank pressure | 4/20mA (Or optional : Modbus TCP/IP) |

| Cabinet | Stainless steel |

| Dimension | 1000x800x330mm (CO₂ : 600*600*250) |

| °C to F | Yes |

| b to PSI | Yes |

| Remote access for assistance | Yes |