The best way to fill your cylinders

PLC & Process, specialized in automated filling systems based around the operators skill.

What are the benefits of choosing Plc Process?

With more than 35 years in the gas industry, PLC & Process excels in crafting cutting-edge control systems using the latest technology. While we serve various industries, our expertise lies in Gas Filling Plants. Our specialized knowledge in PLC Programs and gas expertise enables us to design top-notch filling plants.

ISM ATEX

Plc Process team has advanced knowledge of ISM ATEX Level 2 and our extensive experience in H2 filling validates our expertise in secure design.

Low cost, more efficient

Our products have the best prices and suit different needs, from fully automated to manual, always meeting your budget.

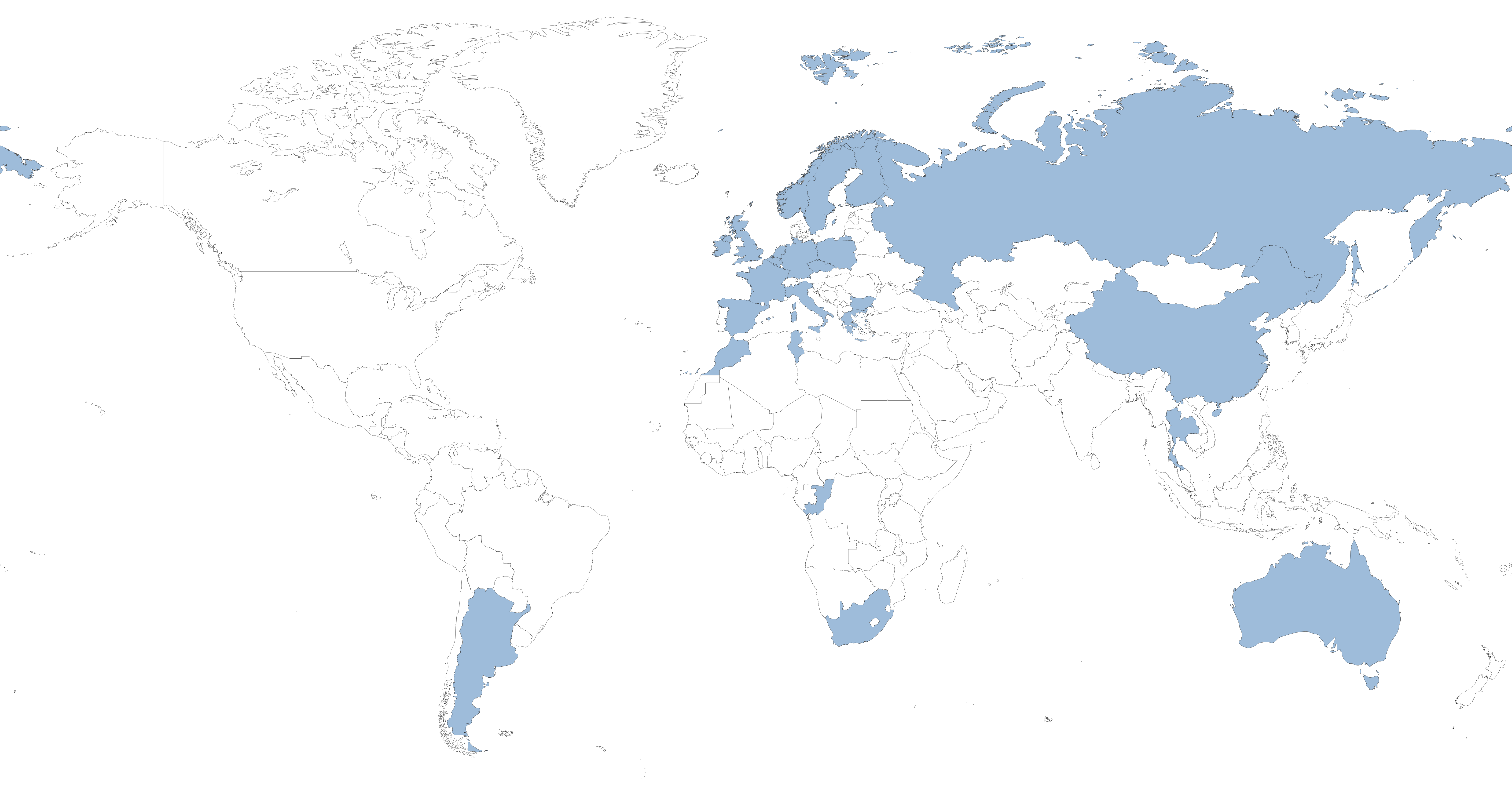

Partner around the world

Proficient team of partners enables us to offer a comprehensive package featuring welders, electricians, and engineers.

They placed their trust in us

The Family Touch

Our unwavering commitment to family values sets us apart from our competitors. We are proud to be a family-owned business making a significant and positive contribution to the gas industry.

World-Class Gas Filling Technology

Dedication to achieving the highest standards has motivated us to design sophisticated control systems that streamline filling procedures, elevate safety measures, and boost productivity. By harnessing cutting-edge technology, we engineer personalized solutions tailored to your unique needs and industry standards.

Your Turnkey Solution

Utilizing our expertise, we can oversee all aspects of a turnkey project to provide you with a fully functional filling plant! This includes piping, valves, filling systems, analysis, cylinder proof systems, and more. Feel free to inquire about anything, and we will take care of it for you!

–

Our team

Committed to our gas product, a skilled team of four oversees the development and engineering of top-tier filling systems worldwide.

Remy

In 2001, Rémy Egea established PLC & Process, leveraging 40+ years of expertise. Initially a technician, he evolved into a capable leader, now leading a 4-member team and involving family in the business.

Remy EGEA

CEO

Alexis

Rémy’s youngest is enthusiastic about the company’s tech. Alexis invents to impress customers and aspires to lead PLC & Process like his father. He is a technical manager, and study and work full-time with Rémy.

Alexis EGEA

Project Manager

Sandrine

Sandrine’s been the admin maestro at PLC & Process. Her export skills earned an AEO certification, simplifying exports and speeding up deliveries. We truly appreciate your dedication and contribution.

Sandrine EGEA

Admin Manager

Edwin

Edwin, our Colombian tech, came with basic computer skills and a strong passion for working in France. Rémy Egea hired and trained him. Now, he excels in creating and customizing software for our screens.

Edwin VARGAS

Technician

600+

Systems running

85%

Export sales

25+

Country reached

–

A neat block of Frequently Asked Questions

Why are Plc Process systems financially viable?

Through the integration of Top Filling with a flowmeter, our clients have observed a notable 10% increase in product yield during the filling process. Additionally, this innovative combination has the potential to slash production time by as much as 40%.

How does PLC Process utilize sensors to boost operator safety?

Employing sensors enhances operator safety by ensuring pressure-free disconnection, closed rack protection during filling, prevention of overpressure, and mitigation of thermodynamic risks.

Does Plc Process system match safety requierement ?

Our systems provide comprehensive traceability and automatically generate reports for medical, industrial, food, and specialized applications, ensuring efficiency and safety across various sectors.

How long will my filling plant be paused to install Plc Process systems?

Production runs uninterrupted most of the time. We can carry out system installations over the weekend, ensuring a swift transition from your old setup to the new one.

What if I can’t find the perfect gas solution on the list?

There’s no need to worry! Plc Process is dedicated to serving the gas industry. Feel free to contact us via email to talk about your needs, and we’ll offer you excellent suggestions!

Can Plc Process connect with my existing systems?

Using our advanced communication technology, we have over 650 communication protocols available, ensuring seamless communication even with legacy systems.